Prototyping / Pre series!

Unleash the Power of Prototyping!

Imagine hitting the 'start' button on your production and then realizing you've made a costly error. Nightmare, isn't it? Prototyping in machining can save you from this havoc by helping in early detection of these kind of hiccups.

Let's dive into an example. "Few years back, as a fresh-faced engineer, I was entrusted with the responsibility of managing a high-volume production project. Full of energy but slightly overwhelmed. What did I do? Took a deep breath and started with prototyping. I acted on this crucial step because I knew, like a diamond in the rough, it helps identify and rectify errors before they become expensive headaches."

Strong know-how and processes

Hollmen has been making prototypes since 1997, we have overcome many challenges and enabled many excellent development projects. If the matter arouses thoughts, contact us and let’s solve the Proto needs together.

We are strongly renewing our machine base and have the most precise machines on the market for machining needs.

We Understand that speed is an asset in Protos and Pre-Series

In individual deliveries, we can deliver from a few days to a few weeks, depending on the complexity of the part. In pre-series, we have the opportunity to create a production line and start pre-series production in a few weeks.

Laser Welding offers an unbeatable opportunity

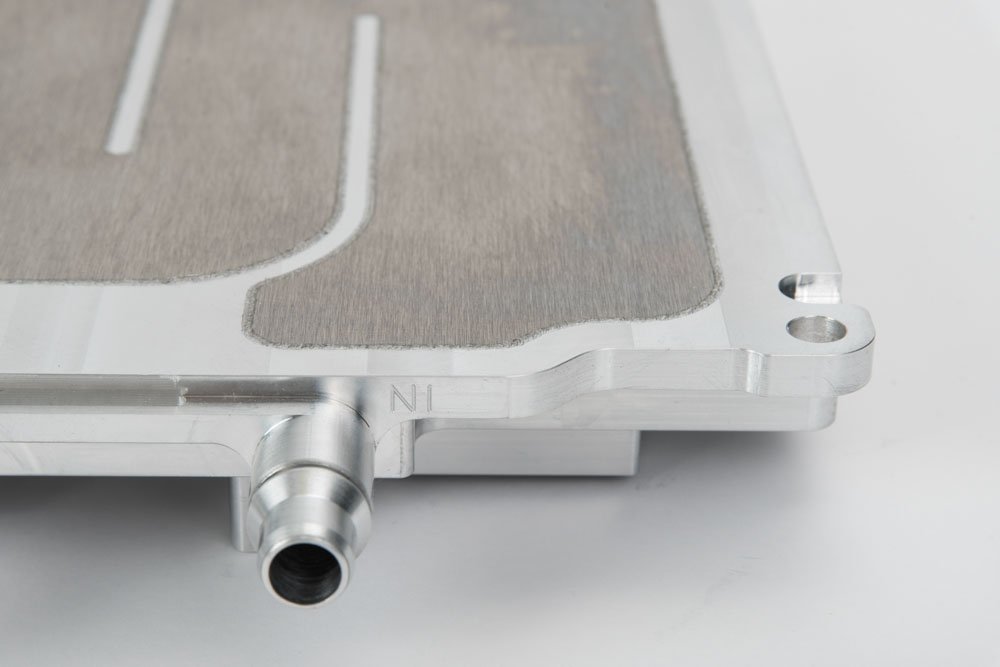

Laser welding technology supports prototype production, in the picture below, for example, the lamellaes are welded to the base plate. We can achieved excellent cost structure by combining different solutions.

Connectors for example can also be welded to fluid-circulating channels and the channels can be closed by laser welding. In laser welding, there is no need for expensive and time-consuming fasteners, we just need the part and the table.

We can gas-tightly connect different aluminum alloys, extrusions and castings to each other, all can also be connected crosswise.

Copper can also be welded, aluminum-copper cross-welding is also possible, including nickel-plated copper.

The whole is what matters

Surface treatments, seal extruded (FIP) and assembly work are part of the process we. We can streamline operations. This is a real advantage because the determinations run according to internal processes and quality is thus ensured.

Simulation

Enhanced Performance: Achieve optimal heat dissipation, maximizing the performance of your power electronics.

Juha will gladly tell you more, juha.haaslahti@hollmen.com

“Pre-series production serves as a crucial bridge between prototyping and full-scale manufacturing.”

"Seeing is believing" - Prototyping allows us to visualize ideas in tangible forms.”

“Embrace the philosophy of "fail fast, succeed sooner". Prototyping uncovers flaws early, enabling rapid iterations and saving invaluable time and resources down the line.”

“Laser welding enables a highly efficient process, savings arise because fasteners do not need to be designed and built, also enables a smaller starting blank. Different materials can be cross-welded and the seam is hermetic.”